Research at Creative Machines Lab

Food 3D Printing

A "food printer” is a 3D printer that prints edible materials. Most 3D printers today print in plastic and in metal, and are revolutionizing industries from aerospace to medicine. Our goal in this project is to develop a 3D printer for fabricating edible items by computer-guided deposition and cooking of edible pastes, gels, powders and liquid ingredients (e.g. flour, water, eggs, butter, and protein). We believe that a food printer is the “missing link” that could bring the benefits of personalized data-driven health to people’s kitchen table.

You want to bake a special cake for your mom, so you boot up the 3-D printer in your kitchen. Loaded with a dozen cartridges filled with pastes of chocolate, marzipan, and other ingredients, the machine downloads instructions from the Internet. You key in a specific texture, size, and flavor, and then you insert a 3-D message in the center—Happy Birthday, Mom!—to be revealed only after she takes a bite. The machine does the rest, assembling and baking a pastry so scrumptious it rivals a virtuoso chef’s in richness and complexity. Your mother loves it so much that she insists you send a slice of the same cake—in the form of a digital recipe—to your Uncle Norman’s printer as well. Your 3-D cake recipe gets so many raves, in fact, that you decide to sell the recipe online for 99 cents a download.

Laser cooking is a software-controlled cooking technique that uses the heat from lasers to cook food products. Because lasers can provide precise spatial and temporal control of heat, we can tailor the heating and fine tune parameters such as laser power, exposure time, light wavelength, and a host of other variables to optimize heating to achieve desired cooking for different foods.

While this technology could be used as an augment to other cooking appliances (i.e. in a microwave for controlled browning on the surface of foods), it's high-fidelity and low thermal penetration make it an ideal candidate for a food printing application. Integrating this technology with a food printer would provide end-to-end cooking and personalized meal creation on a per person basis.

Thus far, we have been investigating the heating effects of mid-infrared lasers (10.6 microns), near-infrared lasers (980 nm), and blue lasers (445 nm) on various foods; namely, dough, chicken, salmon, and vegetables.

Wavelength of the laser light being used for cooking is a key determinant for depth of heat penetration in laser-cooked foods. Through our studies (below), we found Infrared lasers are best for browning the surface of foods and blue lasers are more well suited for penetrative cooking. Multiple laser wavelengths should be used for optimal cooking.

3D food priting (3DFP) is an application of addittive manufacturing that combines the convenience and culinary excellence of a professional chef at the press of a button. This data-driven health approach allows for the creation of custom meals that are particular for each person’s biometric needs. Below is a rendering of the 3D printer that can house up to 18 ingredients, with 2 cooking lasers (IR laser and blue laser), and a heated bed to keep foods warm.

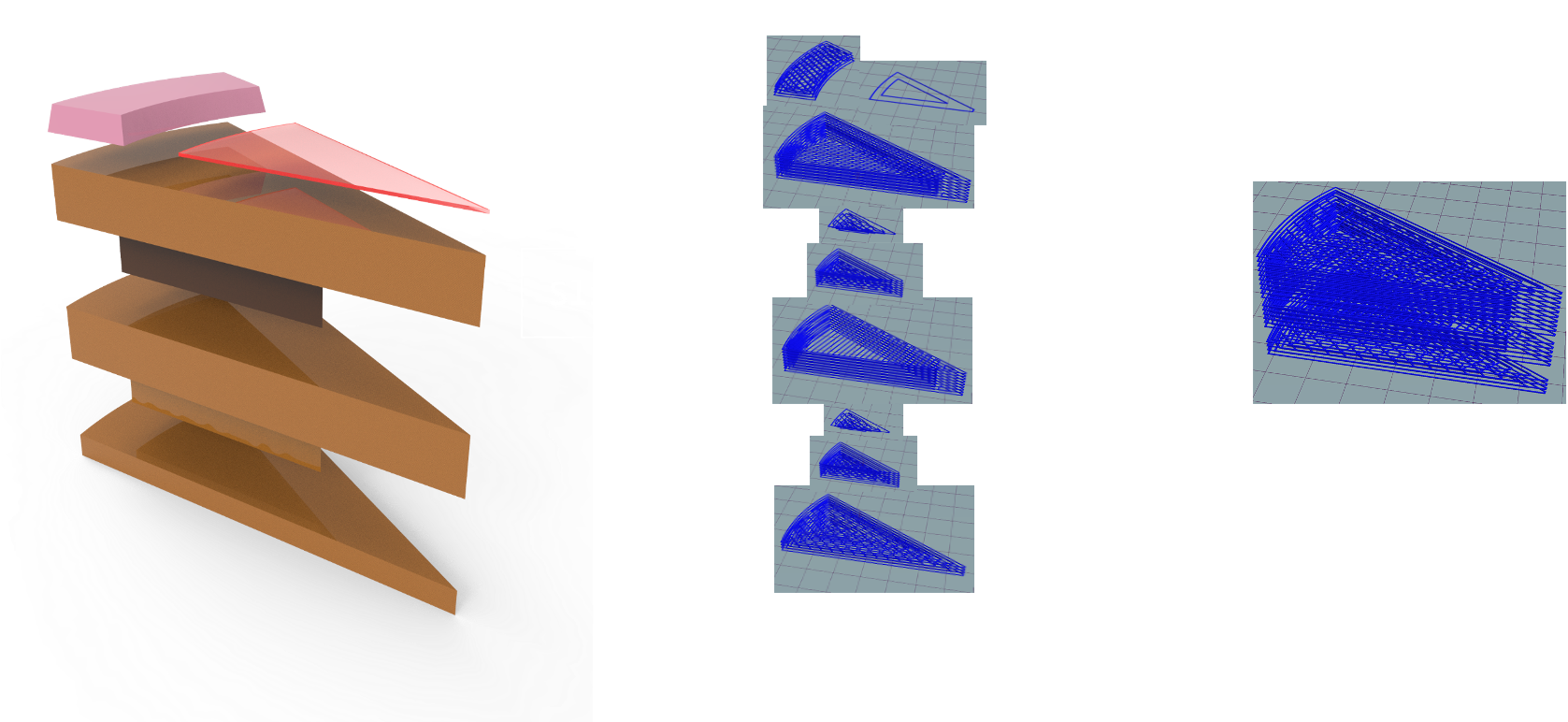

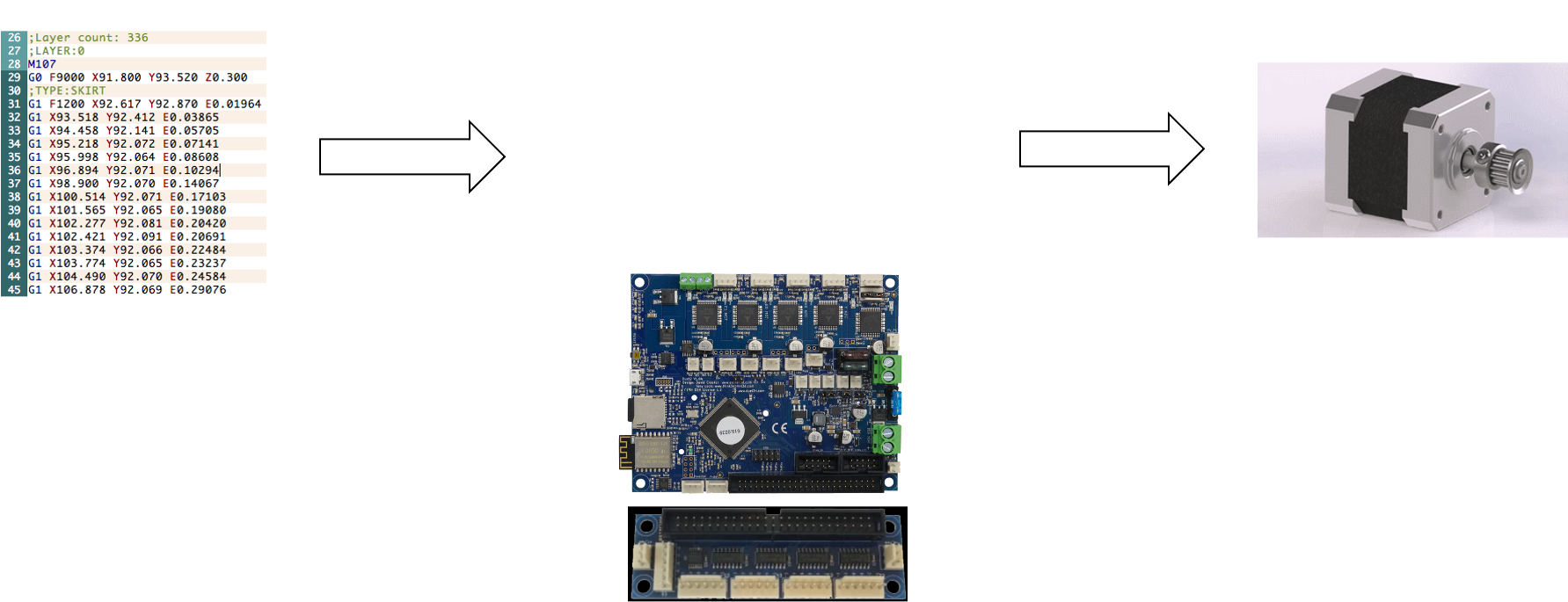

From a CAD design, the .stl file is inputted in the slicer that requires specific informations (nozzle diameterl material flow rate, etc.). The slicer generates a gcode that is sent to the printer.

The slicer generates a gcode that is remotely sent to the duet2 board, and set the commands to start the print.

The customers would be able to order and schedule their food through an app.

Pubblications

J. D. Blutinger, A. Tsai, E. Storvick, G. Seymour, E. Liu, N. Samarelli, S. Karthik, Y. Meijers, H. Lipson, "Precision cooking for printed foods via multi-wavelength lasers", Nature Journal, Science of Food The Manuscript.

J. D. Blutinger, A. Tsai, E. Storvick, G. Seymour, E. Liu, N. Samarelli, S. Karthik, Y. Meijers, H. Lipson, "The future of software-controlled cooking", Nature Journal, Science of Food The Manuscript<.